Product Introduction

1. The structure honing machine use welded and heat treatment steel to get strong structure to supply a strong support for honing processing. After assembled, we would use anti-rust coating with high-quality black paint; make the upper casing of the machine tool sprayed after degreasing, surface adjustment and phosphating. The color is Pearl white (or paint according to customer’s requirements), the machine has a beautiful appearance, smooth lines and a modern sense.

2. The spindle box is driven by a vector frequency conversion motor with a large reduction ratio hard-tooth surface gear reducer, which can achieve constant power

High torque output at high speed, increased cutting force, and it is easy to set the correct spindle speed for parts with different bore diameters.

Spindle power 5.5Kw, speed 5-250r/min. ( Power is based on cutting capacity)

3. Honing head feed expansion system:

Servo motor feeding: The entire feeding unit is installed on the headstock, and the servo motor is extended through a special honing head expansion device

The automatic expansion (also called feeding) of the honing head is realized. This device is connected in parallel with the main shaft. The whole system has a single honing head , which has a large honing range, light weight and self-locking ability, which helps to improve high precision. Expanded servo motor power 400w;

Advantage: The entire machine is powered by electricity. The feed unit can be easily adjusted from 0.001-0.05mm.

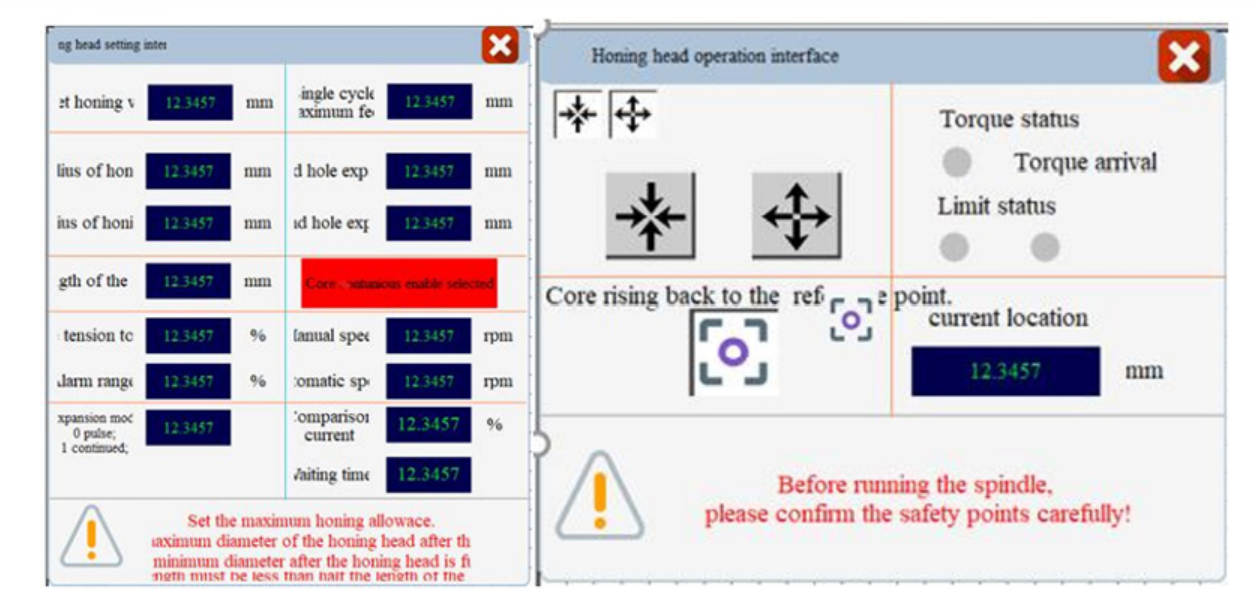

There are three feeding modes, the picture below shows the touch screen control honing head expansion interface.

4. Reciprocating transmission: The servo motor, planetary reducer and transmission chain are combined to form a high-precision fast reciprocating machine structure.

Servo motor power 3.5KW. The reciprocating speed is 1-30m/min. The effective reciprocating length is 1.7m. Reciprocating length setting control circle

The face is as follows:

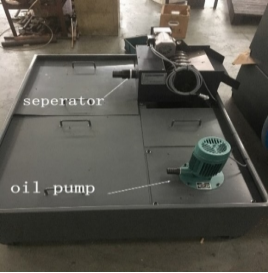

5. The cooling system is a flow of 100L/min, and the honing oil output mode:

High-flow honing oil is injected into the end of the steel pipe to achieve efficient cleaning and maximize grinding efficiency. Honing oil

Tank capacity 200 liters , or customized

The oil injection is controlled by the touch screen, so that injection can stop jetting When the honing head reaches both ends of the steel pipe

For different material processing , we would supply different filter system, for example, for the magnetic metal, we would use magnetic separator system, for non-magnetic material, we could choose paper filter system or pressure paper filter .

6. Honing rod: We have many honing heads to cover 35-350mm , or customized . For example model

①MGC1532 processing hole diameter 38-58mm

②MGC1550 processing hole diameter 60-150mm

The surface of the honing rod is subjected to high-frequency quenching and then cylindrical honing, and the surface finish reaches Ra0.2um.

The inner hole of the workpiece will not damage the smoothness of the workpiece. Both ends of the honing rod are universally connected to automatically compensate the spindle and the concentricity of the inner hole of the piece.

7. The steel tube v-type clamp is the same as the American Sunnen deep hole honing machine, the clamping outer diameter is 40-250mm, or customized .

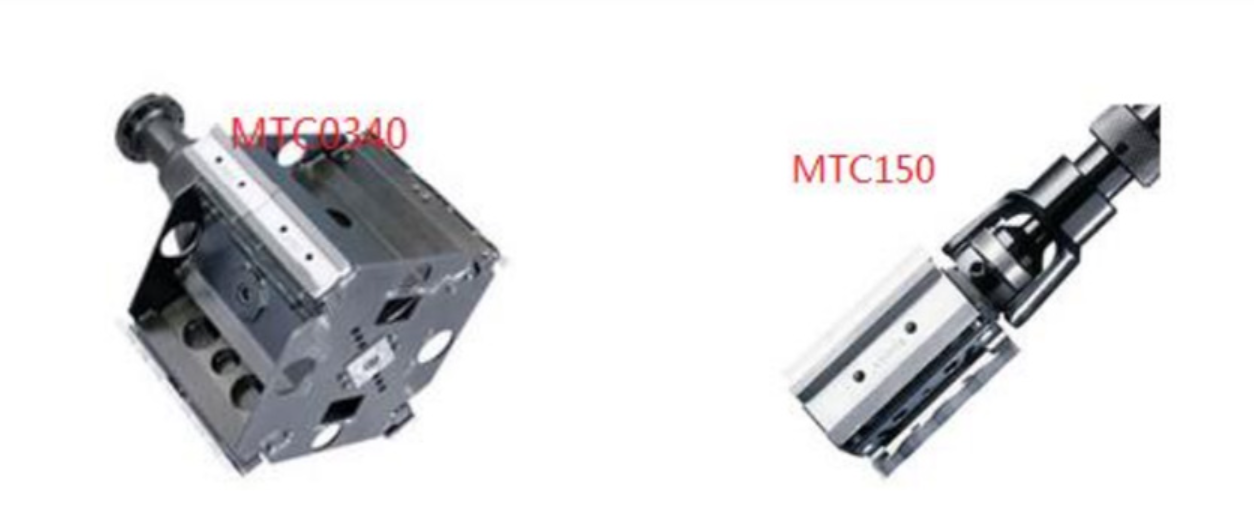

8. Deep hole honing heads: provide the required grinding head according to your company’s needs (below shapes of are the example).

9. Control system: using touch screen + PLC control, our professional engineer design one smart software for honing processing. When operating the machine, the honing tools, the required speed, reciprocation, feed, cooling, and etc. are easy to set, and track processing online , so that operators would control and get good finishing with our honing machine .

The running is set in tough screen to make operation easy. Our online tracking system is very good function to achieve easy operation. This system track working status of the machine tool and the accuracy of the parts, so as to adjust in time to avoid waste generation and equipment damage. At the same time, in order to ensure the consistency of the diameter of the inner hole of the steel pipe,

The touch screen adopts a vertical structure and can be turned 180 degrees. The touch screen automatically alarms when the machine tool encounters a fault.

The faults are following (there are different quotation methods according to the machine configuration):

1. The machining mode is not selected alarm 2. The feed initial reference point is not set.

3. The processing time in timing mode is not set. 4. The machine origin or processing range is not set completely

5. The blind hole parameter setting is not complete 6. The parameter setting of the feed axis is not complete

7. Spindle parameters are not set completely 8 Hardware failure alarm

Company Instructions

1. We are a specialized company engaged in the R&D, production, sales, service and international trade of honing machines and honing tools. It is a fast-growing new force in the industry with strong market competitiveness.

2. The company is composed of international management personnel as well as professional and technical personnel. Adhering to the business philosophy of "customer satisfaction" and "stable quality", we actively promote the spirit of innovation and serve users wholeheartedly.

3. With the rapid development of international manufacturing in the Chinese market and the widespread application of honing technology in aviation, aerospace, machinery, automobile, mold, hydraulics and other industries, the requirements for honing tools are becoming higher and higher. The company cooperates with a number of foreign companies, applies foreign advanced technology, and develops special products, series products and auxiliary products based on the product characteristics of various domestic industries. 4. The DWJ series deep hole honing machine developed by the company has exquisite structure and good technical performance, and is widely used in deep hole processing industry; The small horizontal honing machine developed by the company can be widely used in machining, machining feeding, CNC feeding and other industries. It can meet the needs of different users, and the products are economical and affordable; The honing tools realize mass production and professional design, which can not only meet the requirements of mass production, but also meet the special needs of customers; At the same time, it can be used in Europe, the United States, Japan, South Korea and so on. Imported honing equipment is developed and produced. Machine honing tools and accessories.

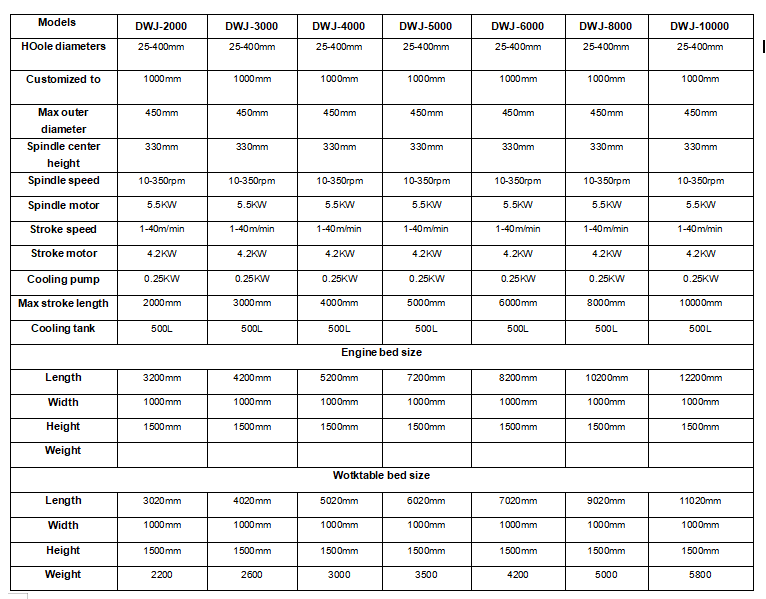

Technical parameters of the machine

1.1 Machine basic parameters

|

NO |

Description |

Description datas |

|

1 |

Machine control system |

Siemens S7-300 , PLC touch screen ( China brand) |

|

2 |

Spindle motor |

YP-50-5.5-6-B5, AC, China brand |

|

3 |

Spindle electrical power |

7.5kw |

|

4 |

spindle speed |

10-350r.p.m. |

|

5 |

reciprocation motor (stroke) |

DANAHER Servo motor |

|

6 |

reciprocation driver (stroke) |

Kollmorgen |

|

7 |

stroke electrical power |

4.2kw |

|

8 |

reciprocation speed: |

1-40m/min |

|

9 |

Max. reciprocation length: |

10000mm |

|

10 |

feed electrical power |

Mitsubishi servo power |

|

11 |

feed electrical power |

0.7 kw |

|

12 |

Engline power structure |

Mechanical three-speed shifs |

|

13 |

maximum clamp outer diameter |

400mm |

|

14 |

clamp way: |

Chain V Jip |

|

15 |

Engine bed coolant system: |

Magnetism fliter system |

|

16 |

Refrigerant maximum current capacity: |

|

|

17 |

Coolant tank: |

500L |

|

18 |

Cooling pump flow |

30L/min |

|

19 |

Refrigerant request: |

Special honing oil |

|

20 |

power request: |

380V,50Hz,3Phs |

|

21 |

Air Pressure Request : |

0.6MP,30L/M Flow |

|

22 |

Layout |

11000*1200*1500mm |

|

23 |

weight |

5800 KG |

Customized Special gun barrel honing machines !

High precision gun honing machine for small long diameters

Main parameters

Aperture range of machined parts: 1.5-50mm

Maximum length of machined parts: 2000mm

Spindle motor power: 2.2KW

Spindle motor speed: 0-1250RPM

Stroke motor power: 2KW

Stroke motor speed: 10-200mm/S

Stroke length: 2200mm

Equipment space: 7500mm *1300mm*1600mm (length*width*height)

Equipment use space: 8500mm *2150mm*2000mm (length*width*height)

Overall weight of equipment: 6500KG

Power requirements: 380V, 50HZ, 3PH

Air source requirements: 5.5Bar (0.55Mpa)

Product Description

The so-called deep hole machining refers to the hole whose length to diameter ratio is greater than 5. In most cases, the depth to diameter ratio of deep holes in deep hole machining is L/d≥100. Such as cylinder bores, shaft axial oil holes, hollow spindle holes and hydraulic valve holes, etc. Some of these holes require high machining precision and surface quality, and some of the processed materials have poor machinability, which often becomes a serious problem in production.

The most commonly used equipment and tools:

Deep hole drilling machine + gun drill / BTA single tube drill.

Deep hole machine + boring head

Roller deep cleaning machines + boring head

We are a Chinese deep hole honing machine factory, have been supplying machines for many years, we have cooperated with other Chinese factories, we can supply the best machine for your budget. Welcome to us!

English

English Español

Español Pусский

Pусский

Lily

Lily