Product Introduction

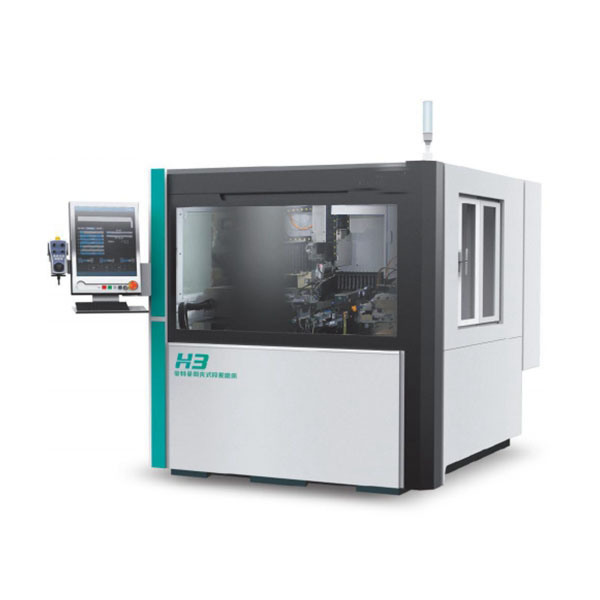

L1200 Ultra

With regard to high-precision grinding of small and medium-sized parts, and in accordance with the world's top grinding machine design and manufacturing standards, WHEELLONG Gold Wheel has launched an ultra-precise universal internal and external cylindrical

grinding machine L1200 Ultra for small and medium-sized parts. At the same time, according to different use scenarios, a variety of options can be configured according to customer requirements.

L1200 Ultra precision all-purpose internal and external cylindrical grinding machine is an ideal ultra-precision external cylindrical grinding machine platform for machining small and medium-sized parts. It can be configured with single grinding wheel straight cutting or beveling external cylindrical grinding head or equipped with digital control rotary shaft B directly driven by torque motor. It can be specially designed according to the user's requirements.

Each production link of the machine tool is strictly in accordance with the highest manufacturing standards. Rich machine tool configuration and wide application range; Strict manufacturing process ensures excellent performance and stable quality; Siemens grinding software is adopted, which is easy to program and use; The highly rigid bed and structure are suitable for the production requirements from single piece to large batch.

Full closed loop

L1200 Ultra is equipped with a Hyd10nm grating ruler as standard, with full closed-loop control. The slewing axis B is equipped with a Hydhigh-precision round grating as standard, and the inspection standard adopts ISO230-2 international standard.

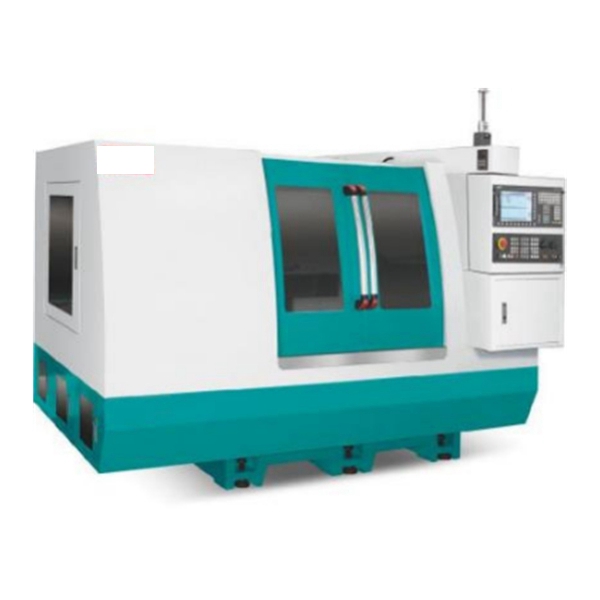

Guide rail

L1200 Ultra external grinding wheel spindle adopts hydrostatic spindle, with high precision, vibration isolation and higher surface quality

The X axis of L1200 Ultra adopts the horizontal double-V guide rail specially designed for grinding machine, which is of high precision and free of creeping, and can realize 0.1 μ micro-feed; Mature and reliable

reinforced V-flat guide rail is adopted for Z-axis, and manual scraping is conducted to ensure high accuracy

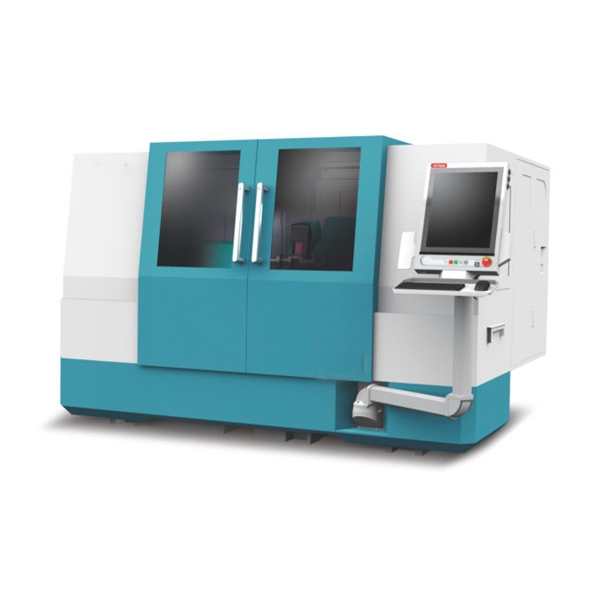

Grinding wheel rack

The L1200 Ultra grinding wheel carrier is of universal structure, which can be installed with up to 2 external grinding wheels and 1 internal grinding wheel. Rotate the direct drive shaft B driven by torque motor to achieve 0.0001 degree accurate indexing.

Outer grinding wheel diameter: max. 610mm

Main shaft power:22kW

Maximum linear velocity:63m/s

Inner grinding main shaft:24000rpm

Main shaft power:22kW

external diameter:150mm

Technical Specifications

(Custom configurations available upon request.)

|

Model

|

L1200

|

|

Distance between centers

|

1200mm

|

|

Height of center

|

225mm

|

|

Maximum workpiece weightsupportedby two centers

|

100/150mm

|

|

Grinding wheel frame sliding X axis

|

|

|

Max Travel

|

400mm

|

|

Movement speed

|

10000mm/min

|

|

Resolution (minimum feed)

|

0.0001mm

|

|

Gratingruler

|

10mm

|

|

Guiderail form

|

Special double-V guiderail for grinding machine

|

|

Table Z-axis

|

|

|

Max Travel

|

1350mm

|

|

Movement speed

|

12000mm/min

|

|

resolving power

|

0.0001mm

|

|

Gratingrule

|

10mm

|

|

Guiderail form

|

Reinforced V-flat guiderail

|

|

Precision index of machine tool

|

|

|

Positioning accuracy of X/Z axis

|

0.004/0.006mm

|

|

Repeatedpositioning accuracy of X/Zaxis

|

0.002/0.003mm

|

|

Grindingroundness of standard testpiece

|

<0.5μm

|

TypicalPart Process Application

|

|

|

|

BT tool shank |

Out of round |

screw |

English

English Español

Español Pусский

Pусский

Lily

Lily