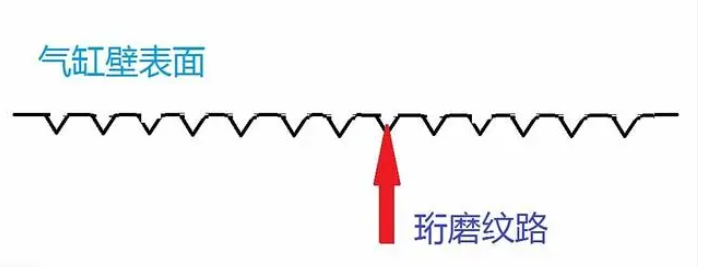

Here I will briefly talk about the parameter of the reticulated angle. The size and uniformity of the reticulated angle have a direct impact on the stability of the oil film and the oil consumption. If the reticulated angle is too large, the oil storage capacity will decrease, resulting in increased friction between the piston ring and the cylinder wall; if the reticulated angle is too small, it will affect the uniformity of the oil film, resulting in poor scraping effect of the piston ring, which is one of the reasons for burning oil.

In modern engine manufacturing, it is crucial to ensure the matching accuracy between the cylinder wall and the piston ring. This can not only shorten the engine's running-in period, but also improve the engine's performance and life. Therefore, before leaving the factory, the engine's cylinder bore will be strictly honed. For those friends who love modification, if you want to expand the cylinder to increase the displacement, please be sure to consider carefully and consult professionals. Because if the correct honing process is not handled, it may have a serious impact on the life and stability of the engine.

Engine hone Video

English

English Español

Español Pусский

Pусский

Lily

Lily